| |

| |

|

Click "BACK" to return to the online catalog |

|

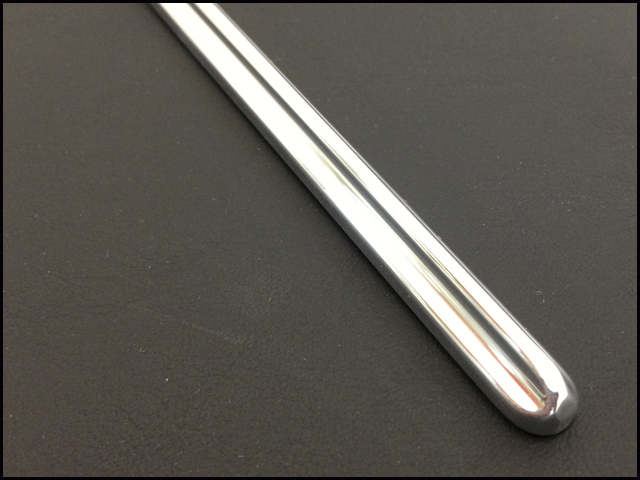

Please note, for international orders (Australia, Europe, etc), we have to cut this trim down to slightly under 1 meter in length.

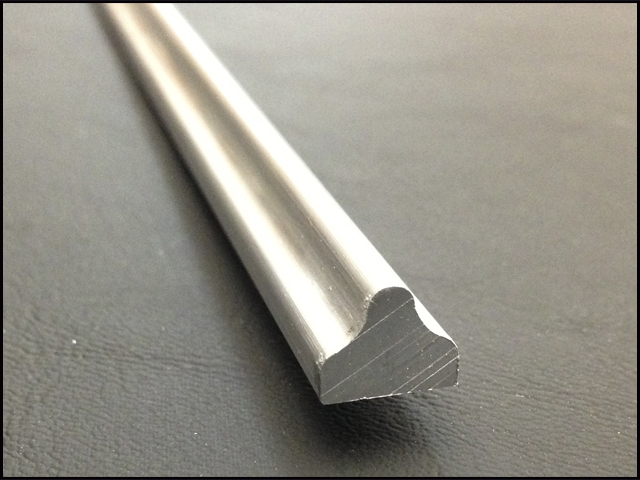

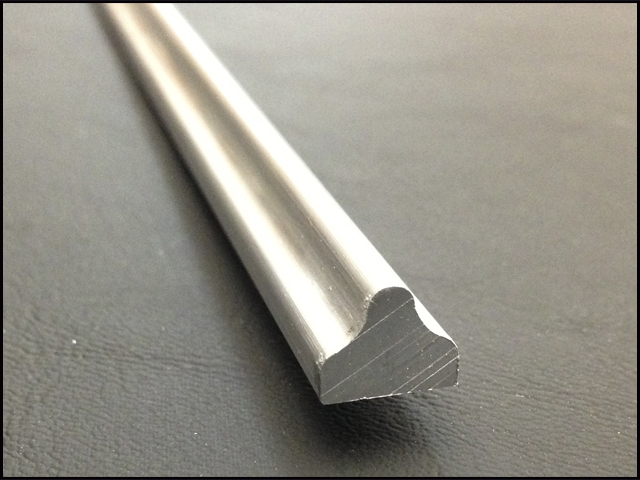

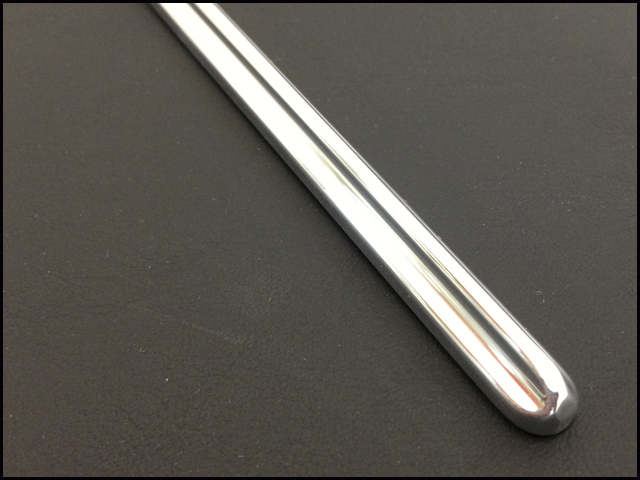

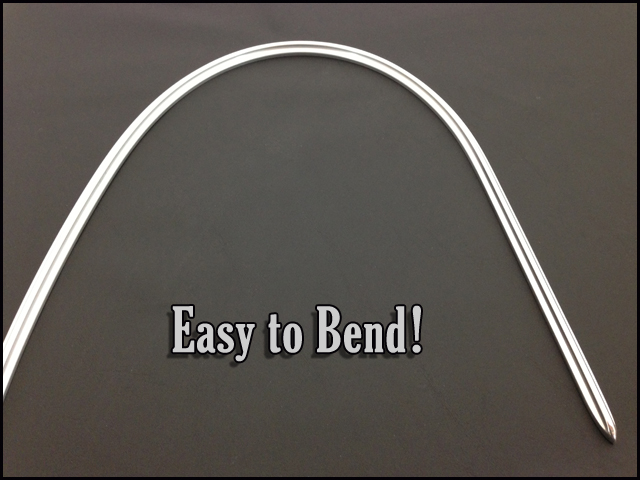

You cut, bend, shape, and polish it to your desired shape!

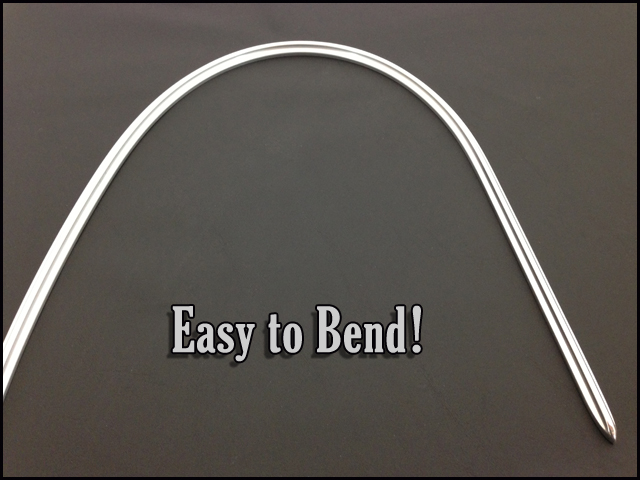

It is very easy to bend, shape the ends, and polish.

Watch for instructional videos soon. |

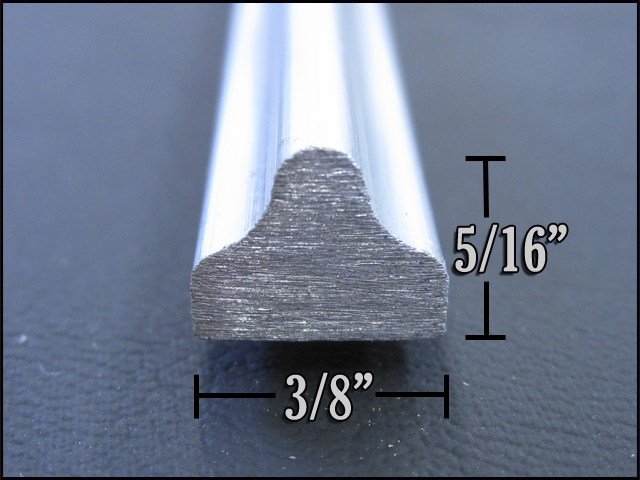

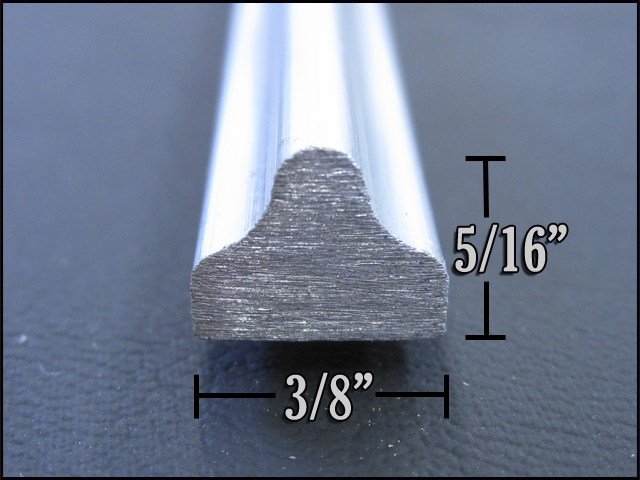

72" Aluminum Trim - $65.00

|

|

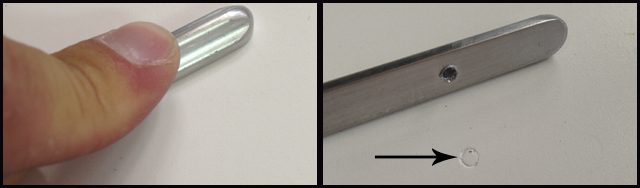

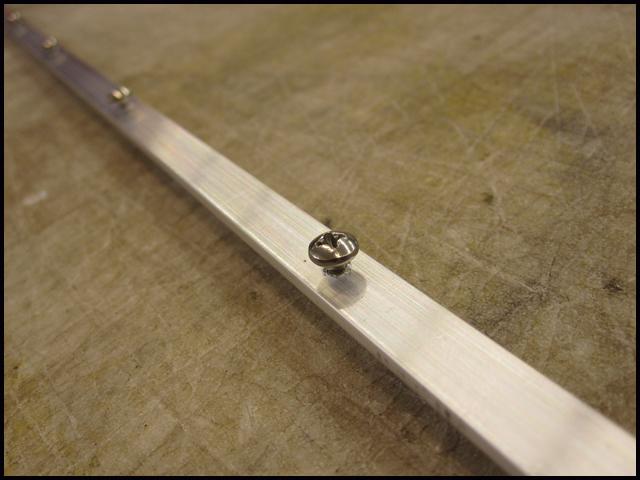

Want us to do SOME of the hard work for you? You can order our trim raw, but with holes drilled on the backside for easier mounting. We supply screws to fasten the trim to panels 1/8 to 3/16 thick. You will receive a piece of 72" raw trim (unpolished), with holes drilled every 4" on the backside of the trim. All cut and/or bent, drilled, polished trim is a non-refundable custom item.

|

72" Pre-Drilled Aluminum Trim

*WE ARE CURRENTLY NOT OFFERING OUR TRIM PRE-DRILLED.

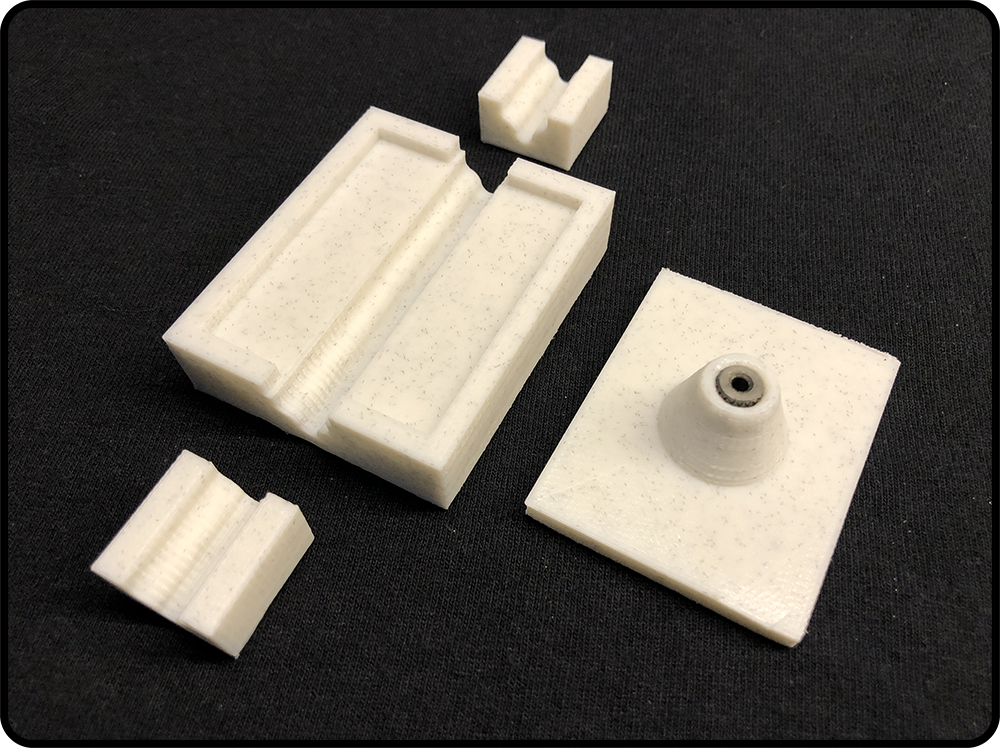

We have drilling fixtures available that help you drill nicely centered holes.

|

| We drill our trim per order, so please allow AT LEAST 2-4 weeks for us to prepare your trim for you. Pre-drilled trim is NON refundable. If you can't wait, our undrilled RAW trim is in stock and ships immediately. All cut and/or bent, drilled, polished trim is a non-refundable custom item. |

|

|

| |

| |

|

|

|

| |

|

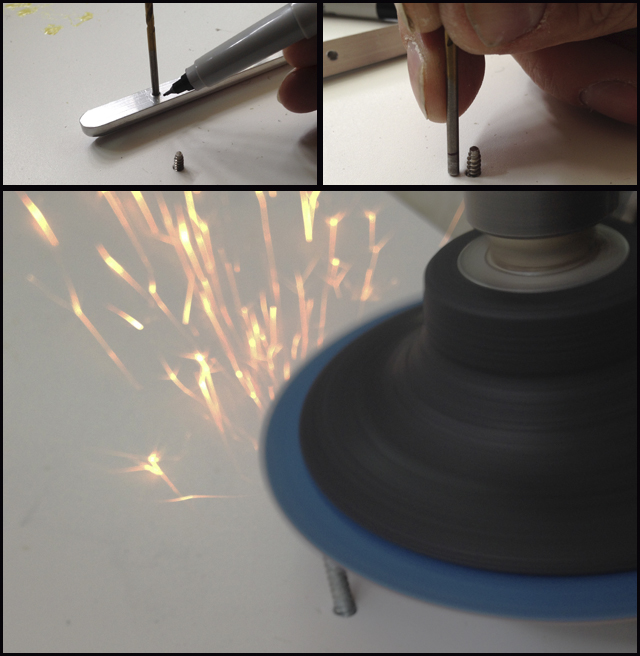

We use an aluminum alloy that is easy to bend. Get creative with this stuff! Our aluminum trim sands very easily with 80 grit sand paper. |

|

|

|

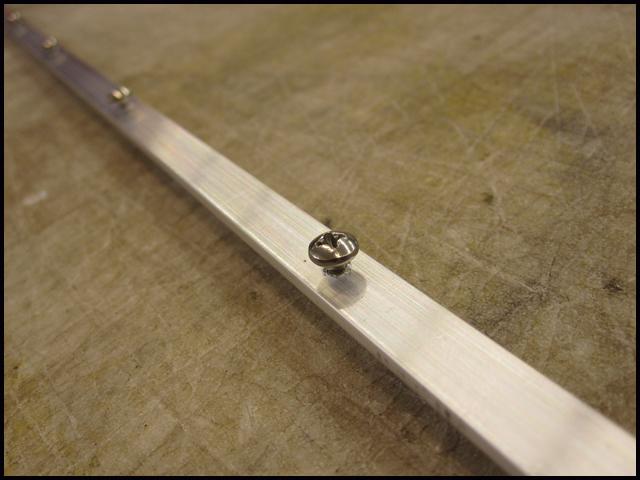

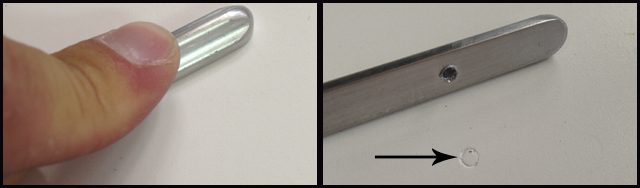

Here are a few tips we found using our trim. After the trim is drilled, do not sand off the "raised ring" left on the aluminum after it has been drilled. When you are ready to position the trim on your panel, firmly press the trim where you want it on the panel. The raised ring left from drilling will leave an impression in your panel where you will need to drill for the screw! |

|

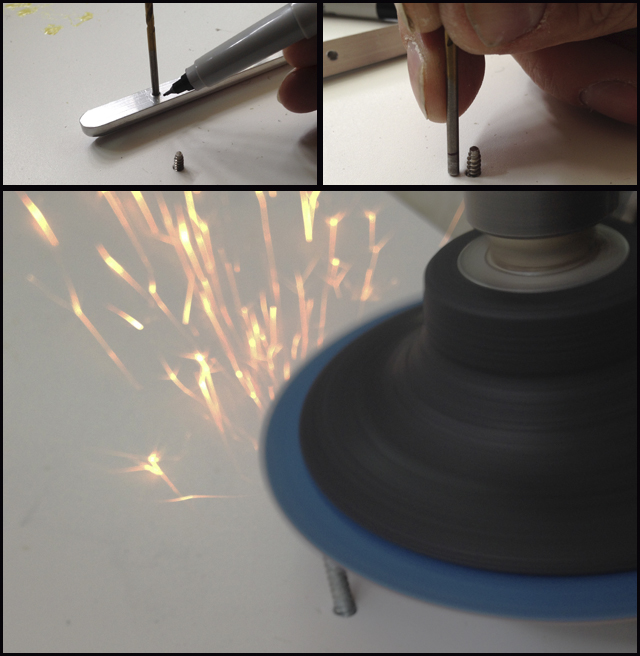

When you are ready to mount the trim to your panel, take a small drill bit or pin, put it in the drilled mounting hole until it bottoms out. Make a small mark on it where it just protrudes from the aluminum trim. This will show you how deep the hole is.

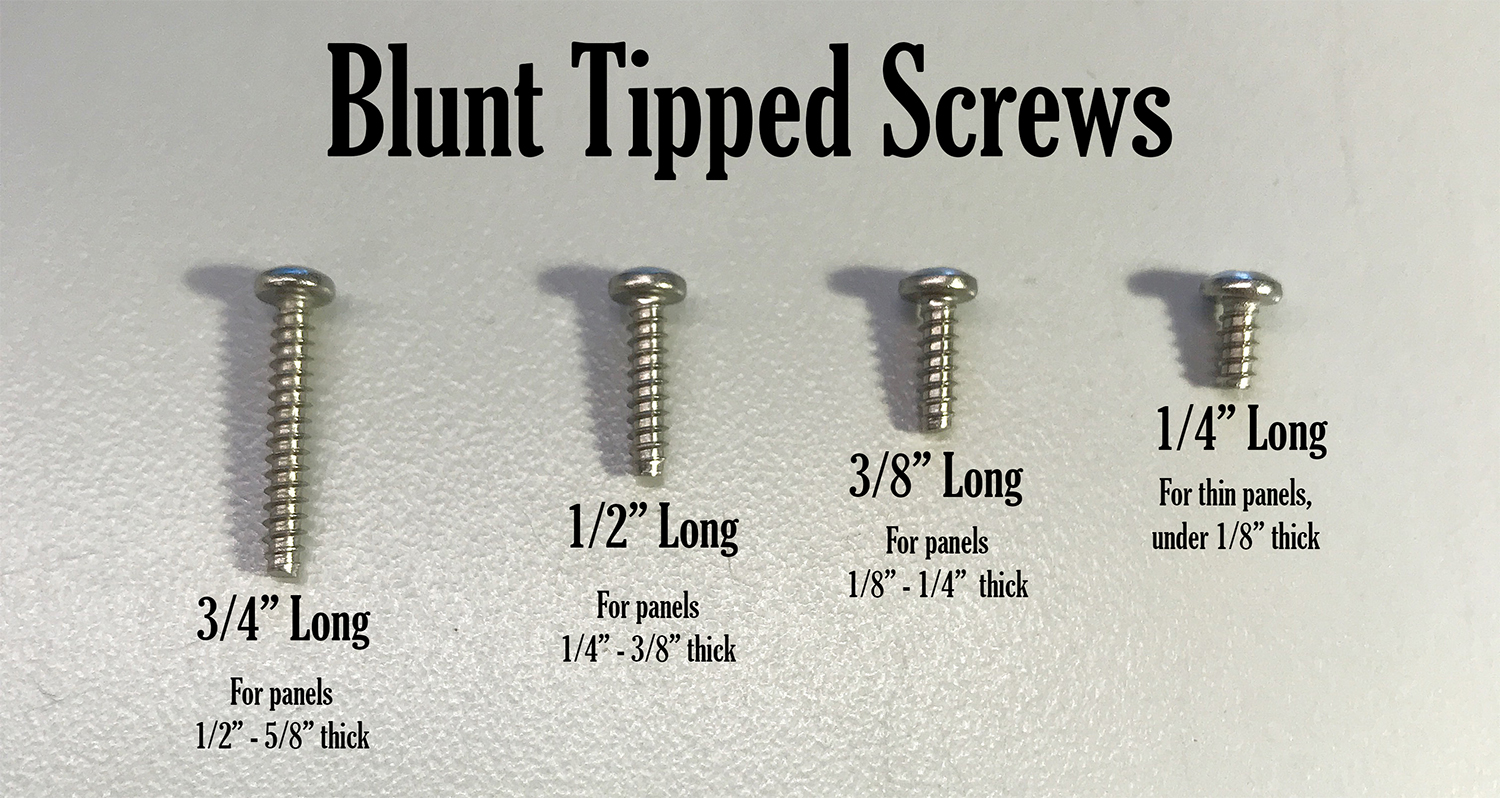

Moving to the second picture, put the screw through the hole on your panel where the trim will be mounted. Put the drill bit or pin that you previously marked next to the screw. This will show you the depth the screw will protrude into the trim. You never want the screw to be taller than the line you marked! If it is, sand or grind the screw down until it is shorter that line you marked. You now know the screw will not bottom out and damage the trim.

We drill our trim with a 3/32" bit, and use #4 sheet metal screws to fasten the aluminum trim to our panels. When attaching the trim, only fasten them snugly by hand! Do not use a drill or electric screwdriver to fasten the trim, and do not overtighten them! Our trim is made from 3003 aluminum, which is softer, so it can easily be bent and shaped. Because of this, the holes can be stripped out if you overtighten the mounting screws. |

| |

|